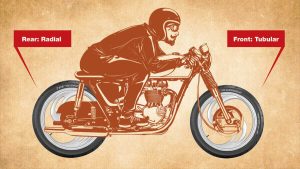

Tyres come in either radial or non-radial (also called zero-radial or bias) construction types. Radial tyres came into existence when companies understood the need for a tyre that could match the high speed of the vehicle and match its performance. Bias tyres have nylon in the material, which may cause overheating when driven at high speeds.

Let us look at the performance difference between radial and bias tyres.

Difference In Performance Between Radial & Zero Radial Tyres

Radial tyres have a unique construction as they are made from a mix of polyester and nylon piles. The tyre belts run at a 90-degree angle with the tread line. Simply put, the tyre is constructed using radial tyres that run perpendicular to the direction of travel. It offers much more contact with the ground. There is less sidewall flex, which results in a comfortable drive. The sidewall and the tread function independently of each other.

Non-radial or bias-ply tyres are made of nylon belts with overlapping rubber piles. The belts run at a 45-degree angle with the tread line. The tread and sidewall, are, therefore, constructed in a criss-cross manner, which means they are interdependent on each other. The resultant is less contact with the ground. It actually means that the strength of both the tread and the sidewall is compromised as they are in the same casing piles.

Performance Differences

Radial tyres provide optimum performance at high speed along with proper cornering and sufficient stability. They provide great comfort to the passengers because they have more contact with the ground, leading to more smoothness over longer distances. Since they are made of steel belts, it provides high resistance to punctures and has a tougher construction. There’s less damage to the tyres while driving at high speeds. Radial tyres have a wider footprint, which offers amazing stability of the tyre. Since the tread offers uniform contact, it leads to uniform tread wear.

On the other hand, bias tyres are constructed to perform smoothly in rough road conditions. They can carry heavy loads with immense ease without hampering the stability aspect. They have tougher sidewalls with crosshatch construction or smoother ride on rough surfaces. However, they are less expensive than radial tyres but are not reliable for driving at high speeds.

Tyre Life For Radial & Non-Radial Tyres

Tyre life depends upon the usage. Cut resistance, traction, ride quality, and heat tolerance are a few factors that determine the tyre life. Generally, radial tyres last for a maximum of 10 years. Since they have wide sidewalls, the tread wears uniformly and leads to a better life for the tyres. That’s why radial tyres are a little more expensive than zero radial tyres, but they also offer similar performance.

Bias tyres do not have a uniform tread pattern. As a result, the sidewall and tread wear out rapidly, which leads to shorter tyre life. They are not as comfortable as radial tyres when driving on city roads. The price of bias tyres is less than radial ones but they are also much more likely to wear off in 3 to 5 years.